TOMRA Deploy 3DEXPERIENCE with TECHNIA

Eindhoven, Netherlands

TECHNIA, the #1 knowledge leaders in PLM and Engineering, announced today a milestone in their strategic partnership with TOMRA Food – the world’s leading manufacturer of sensor-based sorting solutions for the food industries.

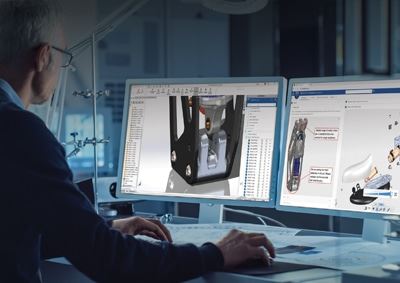

TOMRA Food is a multinational corporation, working to provide sorting solutions for resource optimization. They have more than 50 years of experience in sorting, providing highly innovative sensor-based solutions that help their customers to obtain more, use less and reuse resources to help make the planet more sustainable.TOMRA Food’s aims were to increase data quality, reduce manual oversight and shorten the time to process mechanical changes through their migration from Enterprise PDM (EPDM) to the 3DEXPERIENCE platform, provided by TECHNIA.

The Go Live began with the first successful migration of the TOMRA 3A product data in February 2021. The TOMRA 3A is the most reliable and cost-effective optical sorter on the market. It's specifically developed to provide unrivaled foreign material removal and exceed harvest demands.

TOMRA Food created a custom build interface layer, TOMRA Data Exchange (TDX), on top of the ERP platform (IFS). This made it possible to consume engineering data generated in 3DEXPERIENCE. With the completion of TDX, TOMRA Food was able to effectively perform a comprehensive end-to-end test, which resulted in the successful launch of the program.

TECHNIA are proud to work with TOMRA Food to improve their operational efficiency and provide software, services and support for SOLIDWORKS and the 3DEXPERIENCE platform.

“By making the engineering CAD data accessible through 3DEXPERIENCE, we identified ways to further adapt our engineering guidelines to improve and deploy faster innovative changes on our Food sorter products. Using the

TECHNIA Integration Framework, we now automated the insertion of the updated bill of materials into our ERP system. This significant reduction of manual data entry combined with the fact that the data passed an extensive set of data checks and approval flows in 3DEXPERIENCE, will increase ERP data quality and allow to roll out product changes easier and quicker.”

Nico Bens

PLM Program Lead | TOMRA Food

“When looking back, I'm really proud of how the team has approached and implemented this project. It was definitely a challenge, but due to very capable people on both sides we have now launched a PLM platform at TOMRA and paved the way to reap its full benefits.”

Patrick Kaneman

Team Manager PLM Benelux | TECHNIA